Updated May 24, 2023

The past few years have seen a $72 billion increase in property improvement work compared to a few years prior.

Yet, how many projects have gone unfinished or wasted because of unnecessary errors? (Hint: It's not a pretty number!)

Residential and commercial properties take a lot of money and energy when refurbishing. Concrete floors are a great example of an improvement project that amplifies the space and is money well-spent.

The right project at the best price means understanding how having the right concrete floor grinder in the right size can make your project a success.

Continue reading for our guide to the different sizes of concrete floor grinders and how to select the best choice for your business needs.

OUTLINING YOUR FLOOR PROJECT

Concrete floor grinders are useful for several different polishing or refurbishing jobs. These tools can clean chemical spills or strong adhesives left over from tile or carpeting. They can also smooth out disjointed floors or create a high-shine gloss for a sophisticated look.

When used correctly, a concrete floor grinder is a powerful machine.

Having so many uses means there is a variety of different sizes of concrete floor grinders. Each project needs the correct size to achieve the best result for your property.

When it comes to selecting the appropriately sized concrete floor grinder, it's key that you start your work by outlining the concrete floor project you are undertaking.

.jpg?width=600&height=450&name=OF20Pro%20Diamabrush%20Acrylic%20(7).jpg)

DETERMINING THE PURPOSE OF YOUR PROJECT

The various aspects of the project will each affect your choice of machine. Beginning with this clarity is crucial, so you must ask yourself some questions.

What is the goal of the work? Are you smoothing out rough surfaces or just removing spills and stains?

What is the square footage of the space you will work on? Is this a smaller job (i.e. under 1,000 square feet) or a larger scale (i.e. above 1,000 square feet)?

Are there a lot of edges and corners to clean in the space? Is it more of an open floor plan that needs a lot of work and surface preparation?

These units can be used to complete both big and small projects, but your work can extend in length and frustration if you choose the wrong size at the start of the project.

Carefully answering each of these questions before you begin will simplify finding the best-sized grinder while keeping you on your deadline.

PICKING THE CORRECT SIZE OF CONCRETE FLOOR GRINDER

Now that you have outlined your project, picking the perfect size grinder becomes a matter of determining which style will accomplish your goals.

There are three main concrete floor grinder sizes to understand. Each has particular projects it is perfect for, so understanding all three is vital.

The choices are:

- The Hand-Held Grinder Option

- The Stand-Up or Walk-Behind Grinder Option

- The Ride-On Grinder Option

THE HAND-HELD OPTION

Out of all the concrete grinding options on the market, hand-held concrete grinders are the smallest size. These compact tools, which look similar to angle grinders, tend to be used for edging a given space and getting flush with the wall.

These units also tend to be the primary choice for getting into hard-to-reach places with even strokes. Part of the tradeoff is that hand-held units take more manual labor than the other types of concrete floor grinders.

In other words, you will be doing most of your project on your hands and knees with this one. This will extend your work time and require more energy to maneuver around an area while applying equal and even pressure.

WHICH PROJECTS IS A HAND-HELD CONCRETE GRINDER MOST SUITABLE FOR?

Still, these grinders are perfect for smaller projects, such as patching up an area on the floor, smoothing concrete counters, or completing a bathroom floor.

Popular sizes for hand-held grinders include 4-5 inches or 7-9 inches.

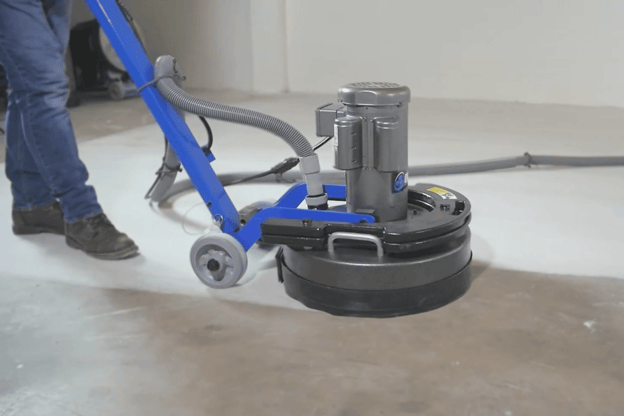

THE STAND-UP OR WALK-BEHIND OPTION

The walk-behind or stand-up grinders are one of the most popular for business or residential projects. These types of grinders cover a much larger surface area than the hand-held units. They also take considerably less energy to operate, so you can complete your projects in a reasonable timeframe.

This style of concrete floor grinder comes in various sizes. What will work best depends upon your project's square footage. A stand-up or walk-behind unit can be as small as 1.5 feet or as large as 3 feet.

WHICH PROJECTS ARE THE STAND-UP OR WALK-BEHIND OPTIONS MOST SUITABLE FOR?

A small stand-up unit is perfect for small-scale residential projects, like a garage. You can use a medium-sized grinder for larger residential projects or commercial builds, such as an outside restaurant patio.

Meanwhile, you would use a larger walk-behind for higher square-footage polishes and evening-out concrete surfaces. Stand-up grinders are a go-to for removing epoxy, glue, and paint from concrete floors.

THE RIDE-ON FLOOR GRINDER OPTION

Your final choice for a concrete floor grinder style is the ride-on option. This type of grinder brings a lot of mechanical torque into the equation.

Ride-on grinders are the largest and most powerful of the three options. These are typically reserved for large-scale, commercial projects. You would use this option for grinding and polishing a warehouse, shopping mall, or complex.

One pass on a ride-on machine will evenly grind 3+ feet of surface area.

ACCESSORIES

Whichever style of grinder you choose, consider other factors that will make your work a more comfortable operation. For example, consider a unit that includes dust control options, such as a dust extraction vacuum or even a simple dust guard.

Apart from making sure your equipment can control dust, you can also look into machines that come with vibration-reduction technology. This can be helpful for projects where you will need to stand up and operate the grinder for long periods.

RPMS AND POWER RANGES

The various sizes of concrete floor grinders each come with different RPMs and power capabilities that make them more or less powerful, depending on your project.

Grinders can be powered by electricity, gas, or propane. Larger pieces of equipment, such as ride-on ones, need more juice to run, so gas or propane is standard.

Diamond shoes are attached to each grinding disc on the concrete floor grinder. Some machines have one large plate with several discs attached (known as planetary). Other units have several rotating discs that move from the force of gears (known as rotary).

All of the discs on the grinders move at different revolutions per minute (RPMs). A more powerful unit will have a higher RPM and thus be more aggressive in its grinding abilities. A low RPM would be around 300 spins on average, while a high RPM would be about 1,300 spins.

You need to be careful about knowing the RPM for the size you are going for because a lower or higher RPM will produce different results. Cleaning a spill at the top of the concrete would require a lower RPM so that it doesn't grind too much concrete away. A deeper removal job would benefit from a machine with a higher RPM.

YOUR CONCRETE FLOOR GRINDER BUYING GUIDE

The size of a concrete floor grinder should be based on your project specifications. The square footage and the purpose of your residential or commercial property will guide you when choosing the best size.

Hand-helds, walk-behinds, and ride-on machines each bring different RPMs and power to buff and polish a project of any scale. Understanding these options is essential for finding the best types of concrete floor grinders to meet your needs.

Do you know what your concrete floor requires? Browse through our inventory of floor grinders to find the best size for you today!

0 comments