Updated April 27, 2022

Choosing the right concrete grinder for your business is important. When making this decision, there are a few things to consider and some tips that can help you make an informed choice.

What are you using it for? How big of a grinder do you need? How much space do you have for storage?

These are just some of the things you need to consider when choosing a concrete grinder. Whether it is for your concrete floors or surface preparation, a concrete grinder will surely do the job!

Read below as we go over everything from size requirements all the way down to price points.

What Are Concrete Grinders For?

A concrete grinder is a machine that helps to smooth and level a surface. Nowadays, most concrete floor grinders are electric-powered, and they come in a variety of sizes.

The smaller electric grinders are typically used for small projects such as home improvement or DIY projects. Meanwhile, the larger electric concrete floor grinders are more often used by professionals for grinding and leveling concrete floors. On the contrary, there are also gas-powered concrete grinders for those who need more power in their machines.

Apart from concrete floors, concrete grinders can also be used for surface preparation. This means that the machine can be used to remove paint, coatings, mastics, and adhesives from a variety of surfaces. They can also be used for removing paint, epoxy, and other coatings from your concrete floor. In addition, they can be used for concrete surface preparation like grinding down uneven surfaces and for removing grout from between tiles.

Some concrete grinders also come with built-in vacuum systems that help to keep the work area clean.

Different Types of Concrete Grinders

Concrete grinding machines come in a variety of types, and each type has its own set of benefits and drawbacks depending on the project you are working on. Below are some of the most common types of floor grinding machines on the market.

Handheld Concrete Grinders

Handheld grinders are the most common type of tool used for grinding. These small, portable tools allow you to get close enough so that your machine will be able to reach hard-to-reach areas—without being too bulky or straining its power source!

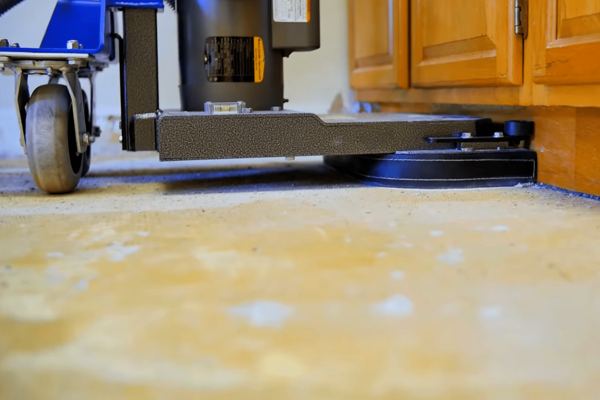

Walk-behind Concrete Grinders

Walk-behind grinders are perfect for larger areas of concrete. These units come in different models and can be powered either by LP, petrol, or diesel engines. They also come with a number of attachments, making them perfect for surface preparation. However, the drawback to using this type of grinder is that they can be difficult to maneuver, and they can also be a bit noisy.

Edge Grinder

With an edge grinder, you can get right into tight spaces and cover a lot of ground in short order. Edge grinders are ideal for use on concrete floors. They allow users to work more efficiently by providing them with leverage when trimming out their edging requirements. This helps them to reach high places or wide areas that need attention.

Diamond Grinder

You heard that right, diamond tools exist!

The diamond grinder is an expensive unit to purchase, but it can be used on more difficult surfaces than other types of grinders. The most common are the barrel head and round table models with flat tables, also available for those who have less severe needs in their homes or business settings.

Nonetheless, it's always good practice when looking into purchasing any home improvement item like this one, to do your research on the best types and brands for your needs. By doing this, you can be sure that you're getting the most value for your money as well as ensuring that you're getting a machine that will do the job right and last for years to come.

How To Choose the Right Grinder For Your Needs

Now that you know what concrete grinders are for and their many applications, how do you choose the right one for your needs?

Here are some more factors to consider when choosing a concrete floor grinder:

Purpose

Will you be using it for grinding, polishing, or both? How large of an area will you be working on? When choosing floor grinding machines, always consider the purpose and where they will be used. Do you need it to polish concrete floors in commercial buildings or just to do some light grinding?

If you are mostly working on smaller projects or DIY projects, then a handheld concrete grinder would be a good option for you. These grinders are small, lightweight, and easy to use. They also come with a variety of attachments to help you get the job done.

If you are working on a larger project that requires more power, then a walk-behind grinder would be a better option for you. These grinders are usually powered by LP, petrol, or diesel engines and can cover a lot of ground quickly. However, they can be difficult to maneuver.

Assess first the job you need to do. Is it for residential home projects or a commercial space? Do you need a floor grinder that will get into tight spaces or edges?

Before you break the bank on your new toy, check first what you need it for so you will better know and understand which floor grinder you need.

Wet Grinding vs. Dry Grinding

Another thing you need to know before you go out and purchase a grinder is the difference between wet and dry concrete grinding.

Wet Grinding

Water is an essential ingredient for concrete grinding. It not only cools down the diamond tooling and provides lubrication to reduce friction, but it also prevents overheating.

Overheating could lead to the melting of epoxy resin or glazing over due to the high temperatures generated from work-related stress on materials used in the grinding process. Wet grinding is typically used in the early stages of grinding or polishing concrete floors.

Dry Grinding

Dry grinding is the process of grinding concrete without the use of water. This method is used when a high level of finish or a very smooth surface is not required. It is also used on surfaces that have been previously treated with an acrylic sealer or coating.

The latest technological advances in dry floor grinding machines or concrete floors have resolved one of the greatest setbacks to date, which is dust exposure. Newer models are now fitted with extraction systems and filters for minimizing operator or environmental health during operation as well. This method simultaneously grinds but also cleans, leaving behind a polished surface ready to be applied!

The lack of slurry in this method means that you get to save time when cleaning up. It also gives a far better shine and finish compared with wet concrete grinding. This is also applicable when polishing concrete countertops!

However, if you are dealing with very hard concrete, then it is recommended that the wet grinding method should be used first and then switched over to dry afterward. The dust extraction system on these machines can make them more expensive than other types of equipment, but they will last much longer without getting clogged up or damaged by fine particles within your mix.

Type of Concrete

Not all grinders are designed to work with all types of concrete. You need to make sure that the floor grinder you choose is capable of grinding the type of concrete you have.

For example, diamond grinders are designed to work with harder surfaces than other types of grinders, which is why they are best used for specialty applications. Metal bonded diamonds are used on the harder surfaces that require aggressive grinding to remove concrete coatings or to prepare the surface for coating.

Weight

How easy should it be to move your grinder around? Do you need a floor grinding machine that is portable or one that stays in one place?

If you need a machine that is easy to move around, then you should consider getting a handheld concrete grinder. They are lightweight and easy to use. However, if you want to polish commercial flooring, then you will need a walk-behind grinder.

Budget and Price

So you're looking to buy a floor grinder? It's important that before making your purchase, the type of work it will be used for needs consideration. For personal use, some can make do without features such as heavy-duty motor ports, which might cost more than $200 but could save money in other areas down the line.

The price range on these machines typically starts at just under $200 and can go up as high as $4,000 depending on the features and the particular models that are available, like high efficient motors or water cooling systems. That being considered, ensure all the information is taken into account when looking to purchase one of these machines.

Corded or Cordless?

Corded machines have been around for a long time and work well when there's access to electricity, like for residential homes. But if you're working outside of continuous power, such as on location or during emergencies without any nearby sources available at all times, then consider getting one that operates via batteries instead. These types come in various capacities so they can match what your needs may be.

Noise Reduction Capability

Grinding hard surfaces is no easy task. It can be quite the challenge to get through these types of materials without making too much noise, especially when there are a lot of them. It might be important to you that the machine you're looking to buy has the ability to reduce noise levels to avoid any type of distractions or noise complaints.

For this reason, it's important that you look for machines with built-in sound-reducing features to help muffle any sounds coming out while working in silence mode. Noise reduction is a feature that you can see in both a handheld concrete grinder and a walk-behind floor grinder.

In Summary

When looking to purchase a concrete grinder, it is important to take all of the necessary information into account. Not all grinders are created equal and some might be better for certain applications than others. By knowing what you will be using the machine for, it becomes much easier to find the best one for your needs.

4 comments