Did you know that, according to IBISWorld, there are 121,876 flooring installer businesses this year in the US? The growth of these businesses in 2021 was 4.8%, and they experienced an annualized business growth of 3% between 2016 and 2021.

As a commercial flooring contractor, you want to take advantage of this industry growth. But how do you do this? By having the right products for grinding the concrete floors you install for clients.

If you don’t know what these products are, then you might not be sure which ones you need and what you can afford to invest in them. This can be stressful.

That’s why we’ve put together this article. In it, we’ll cover the must-have products for grinding concrete floors.

Finally, you can get the equipment you need, making more money over time. Read on to learn more.

1. The Grinder

One of the most important products for grinding floors is the grinder itself. Specifically, when you’re grinding floors made of concrete, you need a concrete grinder. They have different uses, such as polishing, grinding, and cleaning.

Grinders use horizontal discs that spin around so that a rough surface can be polished properly. They also smooth out any rough edges.

Two concrete grinder options exist. First, there are the traditional models, which are bulkier and used for floors and patios.

Second, there is the compact, newer models that you hold in your hand. Usually, these are used to smooth down worktops.

Even though they differ in size, they work in the same way, grinding the concrete floors or surface down so that it’s polished and smooth.

2. The Diamonds

When you’re using a concrete grinder, you’re smoothing down the floors or other surfaces with diamonds. They’re actually doing the work of cutting or grinding, while the grinder is turning the diamonds upon the object being ground.

Usually, synthetic diamonds are the modern choice. This is because synthetic diamonds can be designed to be the desired strengths, shapes, and sizes.

To choose the right diamonds for you, you have to think about grit number and size. These two factors have an inverse relationship with each other. This means that, the greater the size, the lower the grit number—and vice versa.

Small diamonds with higher grit numbers are ideal for polishing and honing, while large diamonds with lower grit numbers are better for aggressive removal.

3. The Bond

The bond is the part of the grinder that holds the grinding diamonds in place. It’s usually made from plastic resin or metal, though the material can vary depending on the use of the bond. The bond has been designed to wear the floors or surfaces at a specific rate.

Depending on the rate, diamonds will be exposed at a certain rate as they break against the floors or other types of concrete surfaces.

The Importance of the Right Type of Bond

It’s important that the bond you use be appropriate to use against the material you’re grinding. Otherwise, the tool could not work properly—or, worse, it could break. If you grind softer floors with a bond that’s designed for harder concrete, the bond will wear out before it’s meant to.

This is because it’s releasing more diamonds before they are needed to grind the softer floors properly.

On the other hand, if you use a bond that’s designed for softer concrete on hard floors, the diamond on the surface will break and the bond won’t be able to cut through the concrete before new diamonds are exposed.

This happens when the bond’s wear resistance is too high, which means that the new diamonds aren’t coming out fast enough.

The Types of Bonds

Even though it sounds counterintuitive, hard concrete surfaces require you to use a “soft bond,” which has low wear resistance. On the other hand, soft concrete surfaces require you to use a “hard bond,” which has high wear resistance.

A way to understand how this works is by understanding how much concrete you’re actually removing when you grind the floors.

Soft floors might release a much larger amount of dust when you grind them than hard floors. When you’re releasing more dust, you need a bond with higher wear resistance.

You can easily remember it this way. If you think you’ll produce more dust, you need a “hard bond.”

Choosing the Right Bond Type

To choose the right bond type for your concrete floors products, you need to know what level of grinding you’ll be doing. For example, if there’s a heavy coating you need to remove, a more aggressive grit will be more effective.

However, if you’re in the final step of polishing and want to remove some scratches, a lower grit number is better. Generally speaking, grit numbers look like this:

- 30/40 grit for general grinding

- 18/20 grit for aggressive removal

- 80/100 grit for concrete polishing

To get started, take a look at the hardness you’re dealing with. Then, try out the tool with the grit number you’ve chosen, monitoring as you grind. Watch out for excessive wear, which shows the bond isn’t hard enough, and poor performance, which shows it’s too hard.

If you notice any of these issues, switch to a different bond type. So that you don’t have to stop in the middle of a job to get more tools or buy new ones, bring each type of bond type with you to the grinding job.

That way, you can adjust to another grit when you need to.

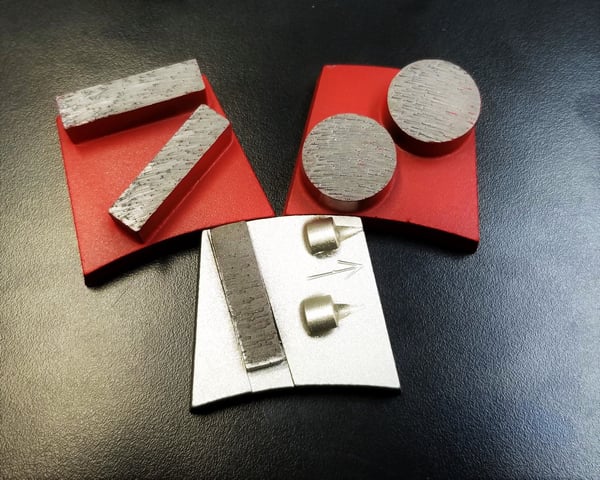

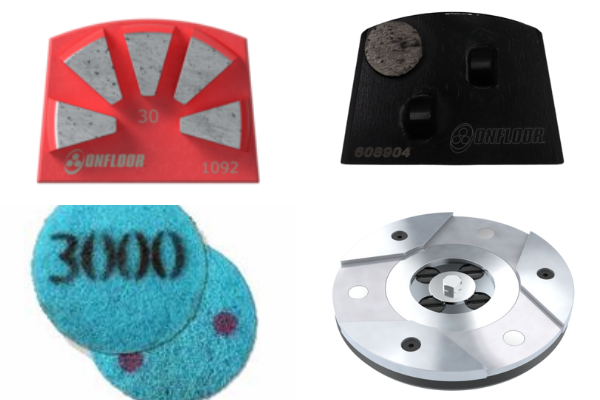

4. Additional Diamond Tools

There are different diamond tools you need so that your grinding of concrete is successful. One of these is the diamond cup wheels. You can switch these out as needed, depending on the hardness of the concrete you’re grinding.

Additional diamond tools include grinding plates, PCD diamond tools, polishing pads, and grinding diamonds. Investing in these will help you keep your diamonds in the right state so you can use them most effectively.

5. Situp Grinder Attachment Kit

To successfully grind concrete, another tool you need is a situp grinder attachment kit. This kit is made of a mounting bracket and welded steel frame. It attaches to the concrete grinder and makes it easier for you to use it if you’re sitting on a stool or mobile chair.

Benefits of the Situp Grinder Attachment Kit

By using the situp grinder attachment kit, you’ll get less tired while grinding. You also won’t put as much stress on your knees and back. It’s one of the best grinding concrete floors products because it saves you time and energy, making you more effective at getting the job done fast.

This also means you can dedicate more time to additional projects.

6. Vacuum Dust Collector

Even though it’s possible to grind concrete floors with either wet or dry methods, many people use dry methods. The reason for this is that the dry method is convenient and faster, and it doesn’t have the same problem of disposing of wet materials as the wet method.

If you’ve decided to do this, one of the products for grinding concrete floors you need is a vacuum dust collector.

How It Works

When you use a concrete grinder to grind a floor, you create a lot of dust. Because there are many requirements that make it necessary to contain the concrete dust so it doesn’t become airborne, you need a tool that helps you contain it.

This is where a vacuum dust collector can be useful. When you use it, only a small amount of concrete dust gets into the air, making the area you’re working in much safer.

When choosing your vacuum dust collector, keep in mind that some are specifically designed for the type of grinder you’ve bought.

You might also benefit from buying protective gear for your workers so that they can safely grind the concrete floors without breathing in any of the dust.

Looking for Concrete Floors Products?

Now that you know about the must-have concrete floors products, you might be curious about where to buy them. Or maybe you want to learn how to use them properly. Whatever information you need, we can help.

At Onfloor Technologies, we’re experts when it comes to concrete floors products. We offer machines, tools, replacement parts, as well as resources and information.

To learn more about how our products can help you, request a demo now.

1 Comment