As a contractor, there's a good chance that you've seen a lot during your time on the job. After all, building up other commercial businesses to house the next growing company leaves you creating a lot of complex projects and handling plenty of challenging demands from your clients. But it hasn't been until now that a client of yours has requested a project that requires a concrete floor grinder to complete the task.

You've never used a floor grinder before, and you're not exactly sure how it works. What's the process for getting one? How do you operate the equipment and make sure that the job is up to par with the needs of your client? Not performing the job correctly could mean the difference between a loyal client and one that will never hire you again, so you have to make sure that you're doing everything right.

No need to worry. This article goes in-depth with how to properly use concrete floor grinders so you'll have no trouble giving your business client exactly what they need. Keep reading to find out more!

When Would I Use a Concrete Floor Grinder?

Before you even learn how to grind a concrete floor, you need to understand why you need one in the first place. There are many times when concrete flooring is covered over with another flooring material, such as carpet or tile, that your client may want to have removed and replaced. The problem is that removing this material often leaves adhesive on the surface, which can often make the concrete look ugly and unprofessional.

Other reasons you might need to use a floor grinder may be because you need to strip paint from the surface or grind off a sealer or other coating in order to add a new coat over it. If any of this applies to you, you'll need to figure out which grinder you need for the job.

The Type of Grinders

As you can tell, there are many different situations where you'd need to use a concrete grinder, and each situation may call for a specific type. There are four main types of grinders: single disc, dual disc, planetary, and edge grinders. You'll want to know when you should use each one.

Single Disc Grinders

As the name implies, a single disc grinder has only one disc, or pad, that's usually around 11 inches in diameter. This is the narrowest out of all of the grinder types, and it's perfect for smaller jobs that are under 1,00o square feet.

Dual Disc Grinders

Where a single sic grinder uses only one disc to get the job done, a dual disc grinder relies on two grinding discs. These two discs spin independently from one another and can cover double the area of a sing disc grinder in the same time. With that said, many commercial concrete grinding jobs are completed using these dual disc grinders.

Planetary Grinders

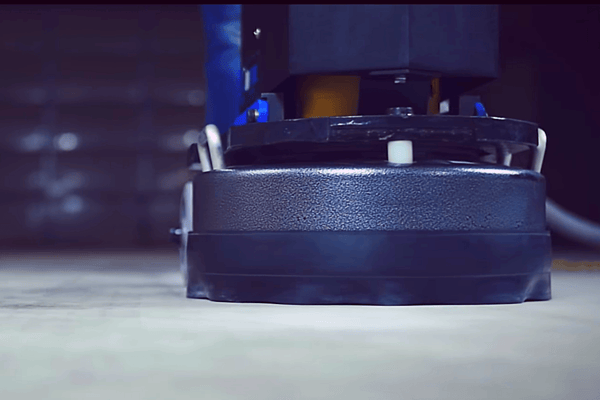

Planetary grinders rely on three grinding pads that spin independently while orbiting around a center point, like planets around the sun (hence the name). These grinders are used to complete large commercial jobs as well as for floor polishing purposes.

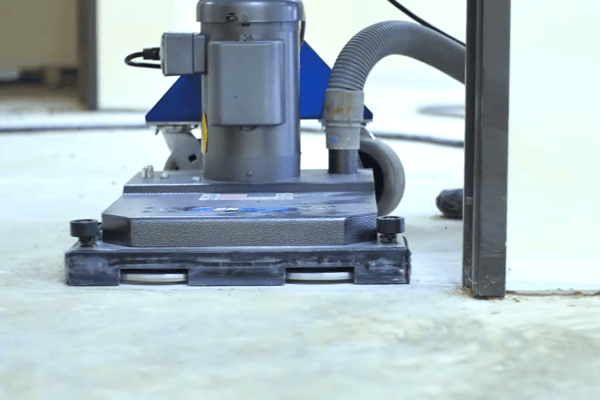

Edge Grinders

Most floor grinders can only get up to an inch from a wall due to their dust shrouds, making the job incomplete. However, edge grinders allow for the operator to reach the edges of a floor and finish the grinding job successfully. This allows for edging work to be completed in a fraction of the time.

How Do I Use a Concrete Grinder?

Using a concrete grinder can seem like a challenge. The good news is that the latest grinders make the job as easy as possible, so anyone can use them as long as they keep safety in mind. However, there are a few factors that you'll want to keep in mind before you use one on your own.

Find the Right Size

Knowing the size of the grinder that you need is the first step to completing your job. Determine the size of the room or rooms that need grinding so that you know the size of the grinder you need as well as approximately how long the project will take.

Identify the Imperfections

The next thing that you'll want to do is locate all of the imperfections in the concrete floor. Knowing where the trouble spots are will allow you to work at a quicker pace and get the job done without going over areas that are already in good condition.

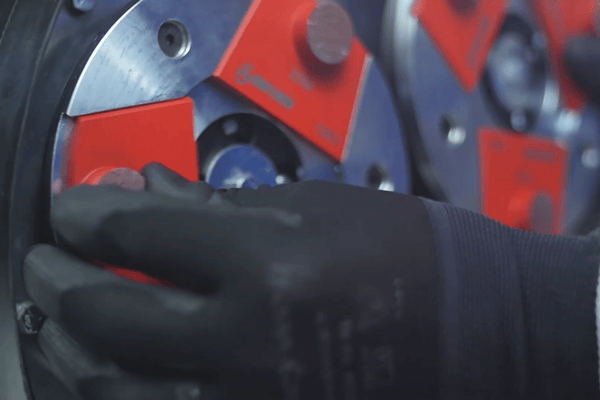

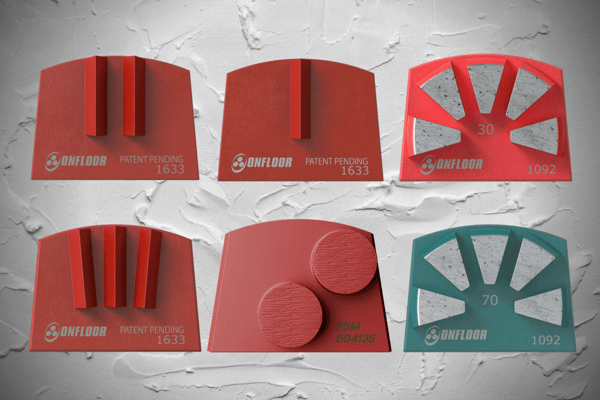

Find the Right Grit

Getting the right grit for your grinding needs can be a bit of a challenge; after all, too much grit could severely damage the floor, and too little grit will have you grinding for much longer than you actually need to be. The best option is to start with a slightly lower grit to cut through the unwanted surface layer, then get a higher grit for a clean and polished finish.

Don't Apply Pressure

If you don't remember anything else, make sure that you don't apply any pressure to the concrete floor grinder. Grinders already do their job naturally without any added pressure, and by placing extra weight on the machine you could end up creating divots that you'll have to remove later, further adding to your work time. Just hold the machine steady, and it'll do the rest of the work.

Let's Get You Started

Now that you know how to use a concrete floor grinder, you should have no problem carrying out the tasks that your client needs to be completed. The next step is to find a company that can offer you the concrete floor grinders that you need to get the job done. We're the right people to help you with your needs.

At Onfloor Diamonds, we know what quality service is, and we make sure to offer only the best to our customers. We have a wide variety of tools and replacement parts, including spring, ridged, and wood tools, diamonds & replacement blades, maintenance and upgrade kits, and much more.

Take a look around our site to see what options we have to offer you, and make sure to give us a call if you have any questions or wish to request a free demo of our goods and services. We can't wait to help you with your needs!

0 comments