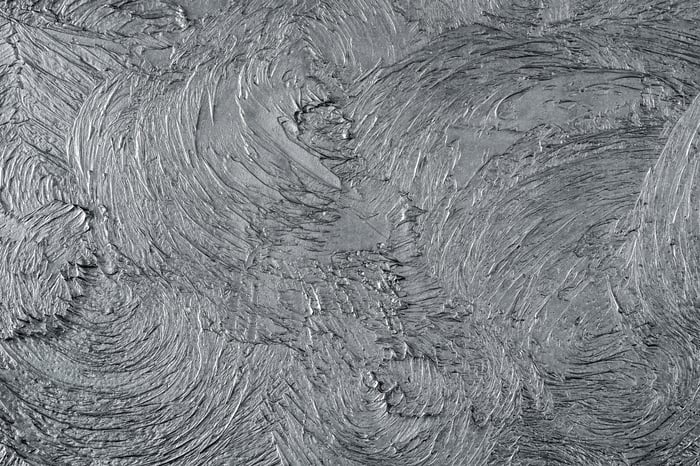

In the pursuit of polished, clean, and modern spaces, the smoothness of a concrete surface might be its sole drawing factor for many. However, in certain projects — particularly those involving the addition of traction to a surface or concrete surface preparation for staining — a roughened concrete surface is not just an afterthought but a fundamental aspect of the design and functionconccon.

It's the difference between a job well done and potential hazards or subpar results.

Whether you are scaling the heights of DIY perfection or looking to finesse your home with professional-grade rough finishing, this comprehensive guide walks you through the intricate process of roughening concrete.

We'll explore multiple methods, from mechanical to chemical and manual, provide a detailed list of gear and tools, underscore the critical safety measures, and wrap up with best practices to ensure your projects maintain a standard that you can be proud of.

Methods of Roughening Concrete

The roughening process is not one-size-fits-all. The method you choose depends on a multitude of factors, including the project scale, the surface area, and the desired roughness.

Here's a brief look at the primary methods:

Mechanical Methods

Mechanical methods involve using powered equipment to abrade the concrete. These tend to be the most efficient for larger floor areas and commercial applications:

- Abrasive blasting: Utilizes a high-pressure stream of abrasive material (for example, grit from a concrete grinder) to roughen the concrete surface.

- Scarifying: Involves removing the thin layer of concrete with rotary cutters to create a textured, roughened surface.

Chemical Methods

Chemical methods alter the surface by applying an acidic solution:

- Acid Etching: Involves applying muriatic acid to the surface, which reacts with the concrete and creates a textured profile by dissolving some of the surface.

.jpg?width=576&height=374&name=3.1.17%20Griding%20in%20Warehouse%20w%20Bar%20(1).jpg)

Manual Methods

When precision and personalized touch are paramount, manual methods may be the way to go:

- Chiseling: Uses handheld chisels to chip away at the surface, providing a roughened finish.

- Wire brushing: Uses a wire brush to texture the concrete's surface and achieve the desired roughness.

Each method has particular advantages and ideal applications. Let’s dive into each, starting with the mechanical approaches, the tools required to execute them, and precautions to observe.

Mechanical Methods: Abrasive Blasting and Scarifying

For many home improvement projects and commercial jobs, mechanical methods offer a blend of efficiency and uniform roughness that can be critical for repeatable results.

Abrasive Blasting: The Art and Safety of Abrasion

Abrasive blasting is a reliable method that involves the use of sand or grit moving at high velocities to roughen surfaces. It tops the list for creating an even top layer at a high speed, with a sandpaper-like finish.

This method requires the following:

- Air compressor: To produce the necessary air pressure.

- Hood and respiratory equipment: Safety first; abrasive blasting can generate harmful fine particles (silica dust) that can cause severe damage to the lungs.

- Abrasives: Different materials provide different coarseness levels, such as steel grit for a coarse finish.

Abrasive blasting is a powerful method, but it's crucial to mitigate its risks, particularly those related to dust and the potential damage to the concrete from excessive blasting.

Scarifying: The Power of Precision

Scarifying machines feature a series of cutting teeth that remove concrete as they rotate, leaving a roughened surface. The key is in the precision and adjustable depth of these cuts.

To scarify concrete effectively, you will need:

- Scarifying machine: The latest models offer depth control, forward/reverse operation, and portability.

- Dust collector: Ensuring a clean working environment and the health of those in the vicinity.

Chemical Methods: Acid Etching

For those looking for a powerful and relatively quick way to etch and roughen concrete surfaces, chemical methods like acid etching can offer unique solutions.

How Acid Etching Works

Muriatic acid is typically used for etching concrete surfaces. This is a precise process that involves protective gear, dilution of the acid, application, and thorough neutralization.

The process includes:

- Inorganic or mechanical cleaning: The surface must be clean of all dirt and contaminants.

- Preparation of the acid solution: Always add acid to water and never the other way around to avoid dangerous exothermic reactions.

- Application and dwell time: Let the acid work (generally takes 5-20 minutes).

- Neutralizing: After cleaning up the residue, neutralize the area with a solution of baking soda and water to prevent further reactions and ensure the concrete is safe to handle.

The Safe Way to Acid Etch

Safety measures with acid etching cannot be overstated. High-quality respirators and acid-resistant gloves are non-negotiable.

Manual Methods: Chiseling and Wire Brushing

When precision and a personalized touch are essential, manual methods come into play, requiring patience and elbow grease but yielding unique results.

The Craft of Chiseling Concrete

Chiseling might be the most artisanal approach to roughening concrete. With a handheld chisel and hammer in hand, you can determine the depth and pattern of chipping:

- Chisels of different shapes and sizes: Depending on the project, you might need a pointed chisel for more control or a flat chisel for surface area.

- Safety glasses: Essential to protect against flying concrete.

- Knee pads and gloves: Always recommended to prevent fatigue and injury.

Wire Brushing: The Underused Gem

Wire brushing is a less aggressive method, making it perfect for smaller projects and applications where the natural look and texture of the concrete substrate are preserved:

- Wire brush with a sturdy handle: For comfort and control.

- Dust mask and eye protection: Even though less dusty than other methods, protection is still vital.

Both chiseling and wire brushing require a steady hand and, more than anything, a clear vision of the final texture.

Best Practices and Tips

Regardless of the method you choose, certain tips remain universal in the quest for a beautifully roughened surface:

- Test an area first: Ensure that the specified roughness will work for your project by testing it out on a small properly prepared surface.

- Work methodically: In straight lines or a pattern, to create an even texture.

- Clean up carefully: Make sure all surface contaminants, especially from chemical methods, are safely removed and disposed of with a reliable vacuum system.

- Maintenance: A rough surface will collect more dirt, ensure your maintenance plan factors in more frequent cleanings.

FAQs

Q: Can I use concrete grinders for roughening concrete surfaces?

A: Yes, concrete grinders can be used to achieve a roughened surface, as well as come in handy for concrete surface prep. They come with different types of grinding disks that provide various levels of coarseness.

Q: Is there any way to speed up the process of roughening concrete surfaces?

A: While methods like abrasive blasting and scarifying can be efficient, it's essential to follow all safety measures and not rush the process. Quick fixes may result in an uneven or unsafe surface.

Q: How do I know which method is best for my project?

A: Consider factors such as the desired surface profile, roughness, size of the area, and safety precautions when choosing a method. It's always best to consult a professional for guidance and recommendations. Overall, the method you choose should align with your project goals and priorities.

Q: Can I use chemical methods like acid etching on all types of concrete?

A: Not all types of concrete are suitable for acid etching. It's essential to test a small area first and consult a professional if unsure.

Q: What steps should I take to ensure safety when using manual methods like chiseling or wire brushing?

A: Always wear protective gear, such as safety glasses, gloves, and knee pads, when using manual methods. It's also crucial to work in a well-ventilated area and take breaks if necessary.

Q: How can I achieve a specific pattern or design with roughening methods?

A: With methods like abrasive blasting, scarifying, and chiseling, you can control the depth and direction of cuts, allowing for a personalized pattern or design.

Q: Is it possible to roughen concrete surfaces without creating excessive noise or dust?

A: Yes, there are methods such as water blasting that use high-pressure water instead of air or chemicals to create a roughened surface. These methods tend to be quieter and produce less dust.

Q: How long does it take to roughen a concrete surface?

A: The time it takes to roughen a concrete surface depends on factors such as the size of the area, the chosen method, and the level of desired roughness. It's essential that you take the necessary time and precautions for a safe and effective result.

Q: Can I use multiple roughening methods on the same concrete surface?

A: Yes, depending on your project goals and the condition of the concrete, you may choose a combination of methods for a desired result.

Q: How do I maintain a roughened concrete surface over time?

A: Regular cleaning and sealing can help maintain the roughened texture and prevent dirt buildup on the surface.

All in All . . .

Roughening concrete is more than just a step; it's an art and a science. Each method has its nuances, and deciding which to employ is almost as important as executing it safely.

As you embark on upcoming projects, give roughened concrete the consideration it deserves, and leverage the right tools such as a concrete grinder from Onfloor to transform both your space and your skill set.

1 Comment